Replacing an aging heating or cooling system involves more than swapping one metal box for another. New and existing homebuyers alike should budget for a range of hidden expenses—from duct repairs and electrical upgrades to filter changes and long‑term maintenance. This guide breaks down every cost factor so you can plan wisely and avoid unpleasant surprises after closing.

1. Base Equipment Cost

A mid‑efficiency gas furnace (80–90 AFUE) ranges from $3,500 to $6,000 installed, while a high‑efficiency model (95–98 AFUE) typically runs $5,500 to $9,000. Central air‑conditioning condensers cost $4,000 to $7,500 for standard 14–16 SEER2 units and $7,000 to $12,000 for 18–20 SEER2 models. Heat‑pump options sit in the same price band as high‑efficiency AC but provide year‑round comfort.

Equipment price also scales with capacity (measured in tons or BTUs), the square footage of each zone, and the total number of zones you plan to condition. A 3‑ton single‑stage system covering one thermostat zone is far cheaper than a 5‑ton variable‑speed unit feeding two floors through motorized dampers. Likewise, ductless multi‑zone heat pumps add roughly $1,500–$2,000 for each additional indoor head beyond the first. If certain rooms have high ceilings, large windows, or solar gain, they may require dedicated zones or upsized air handlers, further raising the equipment and installation cost. When reviewing bids, confirm that each contractor specifies the design load of every zone, the total system capacity, and how many individual areas the quoted system will serve.

2. Installation Labor and Complexity

Electrical Upgrades

Most modern condensers and variable‑speed furnaces draw more amperage than the units they replace. A breaker or service‑panel upgrade can add $500 to $2,500.

Refrigerant Line Sets

If existing copper lines are kinked, undersized, or contaminated with R‑22 oil, new lines and insulation can cost $350 to $800 per run.

3. Ductwork Modifications

Sealing and Insulation

Leaky or uninsulated ducts waste 20–30 percent of conditioned air. Aeroseal or mastic sealing plus R‑8 insulation can add $1,000 to $3,000 but often pays back in two to four years.

Resizing and Balancing

High‑efficiency equipment needs proper airflow. Undersized returns or restrictive branch runs may require new trunk lines or additional registers—budget $500 to $2,000.

4. Filtration and IAQ Upgrades

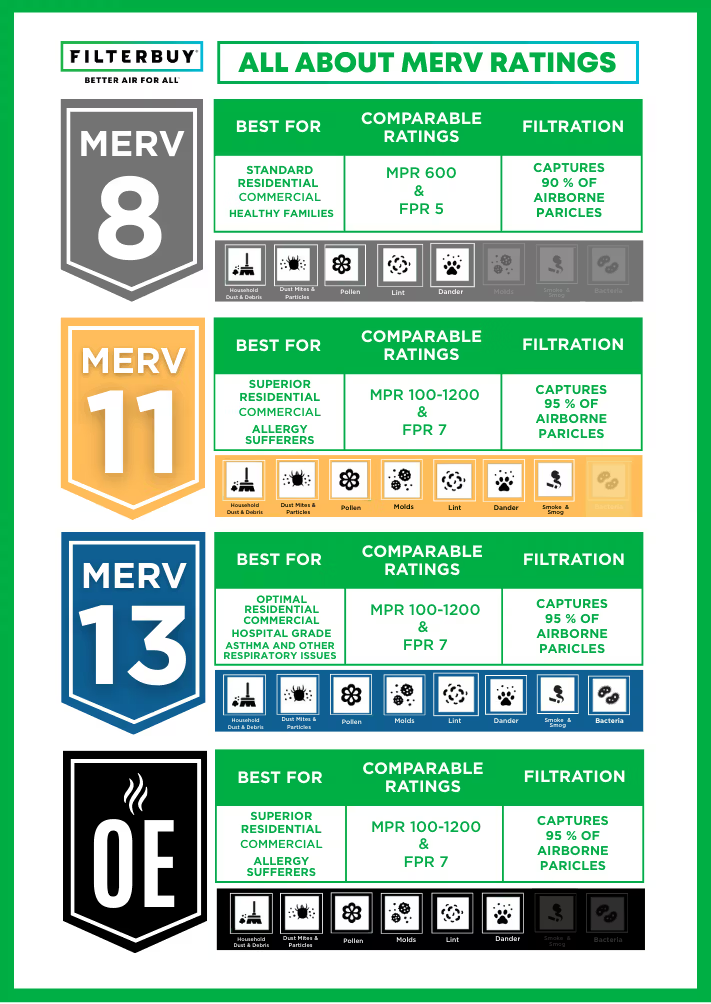

Homebuyers often overlook filter size and type when budgeting for a new system, yet it has a direct impact on air quality, operating cost, and even equipment life. Here are the options you’re most likely to encounter when replacing an older furnace or air conditioning.

| Filter Style | Typical Thickness | MERV Rating Range | Replacement Interval | Cost per Filter | Notes |

|---|---|---|---|---|---|

| Disposable Fiberglass Panel | 1 inch | 1–4 | 30 days | $3–$5 | Original equipment in many 1980‑2000 furnaces; lowest airflow resistance but poor dust capture. |

| Pleated 1‑Inch Filter | 1 inch | 6–11 | 60 days | $8–$15 | Improves dust and pollen removal yet can double static pressure if ducts are undersized. |

| High‑Efficiency Media Filter | 4–5 inches | 11–16 | 3–6 months | $25–$40 | Requires a dedicated filter rack or cabinet; far less pressure drop per square inch than 1‑inch pleats. |

| HEPA Bypass Box | 6 inches+ | 17–20 (true HEPA) | 6–12 months | $75–$150 | Used in allergy‑sensitive homes; adds a dedicated blower or bypass damper. |

Why the jump in cost?

If your old furnace used thin, inexpensive fiberglass filters, upgrading to a high‑efficiency media filter may require:

- A wider filter rack or cabinet ($200–$350 installed)

- An ECM variable‑speed blower motor ($600–$900) to overcome higher resistance while keeping airflow in spec

- Periodic professional cleanings for HEPA or electronic air cleaners ($100–$200 per service)

Static‑Pressure Impact

Higher MERV numbers capture finer particles but can starve a blower if ductwork is already marginal. Your contractor should measure total external static pressure (TESP) after installation and adjust fan speed or duct sizing to keep the system below 0.5 in. w.c.

Real‑World Example

Old setup: 1‑inch fiberglass filter swapped monthly at $4 each ($48 per year).

New setup: 4‑inch MERV‑13 media filter changed every 90 days at $30 ($120 per year) plus a one‑time $250 cabinet install. While annual filter cost more than doubles, the upgrade removes smoke, dander, and even some airborne viruses—valued by many post‑pandemic buyers.

Proper filtration keeps coils clean, maintains airflow, and can extend equipment life by several years, making the added expense worthwhile—especially in homes with pets, allergies, or coastal salt exposure.

5. Refrigerant Type and Future Costs Refrigerant Type and Future Costs

R‑410A remains standard in 2025, but lower‑GWP blends such as R‑32 and R‑454B are entering the market. Repairs on legacy R‑22 systems can exceed $120 per pound of refrigerant, whereas R‑410A hovers around $60–$90. Moving to a new refrigerant reduces long‑term service risk.

6. Efficiency, Capacity, and Operating Cost

A right‑sized 16 SEER2 AC uses roughly 13 percent less electricity than a 14 SEER2 unit. Over a 15‑year life at New Jersey utility rates (18 ¢ ⁄ kWh), that saves about $1,200 on cooling alone. Similarly, upgrading from an 80 AFUE to a 96 AFUE furnace can shave $200–$300 per year off a $2,000 gas bill.

7. Furnace Fuel Types and Their Implications

| Fuel | Up‑Front Cost | Typical Operating Cost | Maintenance Notes |

| Natural Gas | Mid | Lowest in gas‑service areas | Annual combustion tune‑up |

| Propane | Mid | 1.5× natural‑gas cost | Tank lease or purchase |

| Oil | High | Highest fuel variability | Filter + nozzle every year |

| Electric Resistance | Low | 3× cost of gas heat | No flue but highest bills |

| Heat Pump | High | Lower than oil/propane | Requires annual refrigerant check |

8. Maintenance Contracts and Ongoing Expenses

Annual service plans average $200–$350 per system, covering filter changes, safety checks, and priority repair rates. Many HVAC contractors sweeten the deal on new equipment by including the first year of maintenance free, and premium packages sometimes extend that offer to two full years. Taking advantage of these bundled tune‑ups keeps your warranty intact at no extra cost. Skipping maintenance once the free period ends can void manufacturer guarantees and shorten equipment life by as much as five years.

9. Incentives and Financing

The New Jersey Clean Energy Program offers rebates up to $2,000 for high‑efficiency heat pumps and $700 for gas furnaces meeting 95 AFUE or higher. Federal tax credits subsidize 30 percent of qualifying costs (up to $2,000). Many HVAC contractors also provide flexible payment plans, from 0 percent promotional financing for 12–18 months to low‑interest loans spread over seven to ten years. Utility programs and state‑sponsored lenders can layer on additional 0 percent options for up to five years, making a major upgrade cash‑flow neutral for many households.

10. Service Life and ROI

| System | Average Lifespan | Replacement Trigger |

| Gas Furnace | 15–20 years | Cracked heat exchanger or costly ECM failure |

| Central AC | 12–15 years | Compressor failure or leaking evaporator coil |

| Heat Pump | 12–15 years | Capacity loss below 80 percent |

Replacing a 25‑year‑old 10 SEER AC with a 16 SEER2 model can return its investment in seven to nine years through lower bills and reduced repair calls.

Bottom Line for Buyers

Ready for an honest quote? Contact our team today

Ultimate Guide to Furnace Repair Issues in New Jersey Homes

Do Higher HVAC Filters Help or Hurt Your System?

Oil Furnace Won’t Turn On? 8 Common Reasons and How to Fix Them

Electric Furnace Won’t Turn On? Troubleshooting Guide for NJ Homes